Alltask Ltd, have provided access and protection for a major restoration project on Chichester Cathedral’s timber roof. The Cathedral’s roof is of historical and architectural significance. Dating back to medieval times, it represents a key phase of English structural carpentry.

The condition of the roof has been deteriorating for many years, with leaks creating a damp environment and causing the ancient timbers to rot, with water penetrating the interior plasterwork.

In addition, after World War II, when lead was in short supply, the roof was covered in copper, which has caused some major issues as Daryl Vivash, Contracts Supervisor at Alltask explained:

“This lightweight alternative roof covering created concern within just a decade of installation. The coastal wind was forcing the copper panels to lift, leading to fixing the panels with screws to the timber structure so that they would not become loose. Over time the screw holes began to fail, effectively creating a sieve for rainwater to penetrate. Despite continual monitoring and repair, the green copper roofs have reached the end of their working lives, and the timber roof structure requires restoration and conservation.”

The extensive conservation works will be undertaken by Ellis & Co. who are craftsmen in the conservation of historic buildings. The work is being carried out following a fundraising appeal, which saw an incredible £5 million raised for the vital project.

The final, and largest, phase of the major roof restoration on the Cathedral Nave is now finally underway as Daryl explained:

“The Nave roof is of particular importance, as the medieval markings and pegs in this area give evidence as to how these enormous timbers were assembled, and how the craftsmen would have negotiated access without modern scaffolding.

This phase was initially scheduled to commence in July 2020, but the pandemic closed all cathedrals and churches, the Cathedral’s Surveyor of the Fabric advised that the restoration and re-covering of the roof could be delayed for up to two years.”

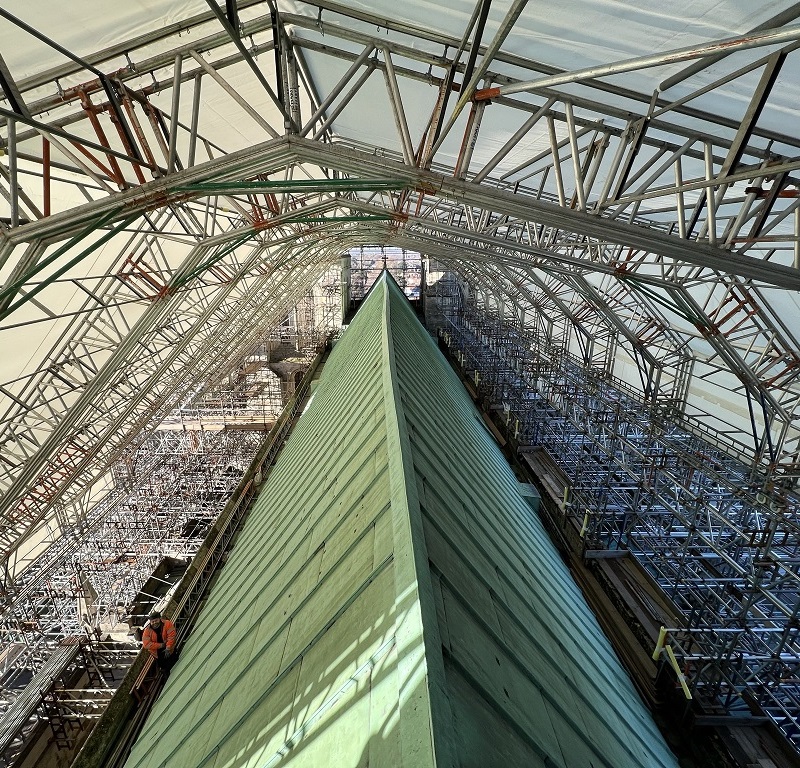

The scaffold, with its many unique challenges, was designed in-house at Alltask by Liam Shearer, Senior Scaffold Design Engineer.

“Although all three phases of the roof restoration project presented their own individual engineering challenges to overcome, this final phase of the project was undoubtedly the most complex.

The south Presbytery wall was deemed inadequate by structural engineers to support any loads from the scaffold structure. Therefore a typical, symmetrically shaped, temporary roof frame was not possible. After careful consideration of where to safely transfer the scaffolds reactions to the existing structure, an asymmetrical, multi-span roof was opted for using the Hakitech 750 rolling roof system.

All of the scaffolds bearings onto the existing structures parapet walls and buttresses were protected using high density polystyrene cut into the walls profile. This ensures that the imposed loads are safely spread over the required area of stone to prevent any damage.”

The design was not the only challenge that Alltask faced with this project, Daryl continued:

“Members of the public presented a significant risk to our works, as a huge amount of material had to be manually transferred from the loading area at the front of the Cathedral to the rear using the same pathways as the general public. This risk was carefully considered and mitigated using designated material routes.

There were also a lot of restrictions around noise and working times that arose due to the Cathedral remaining open, the team had to cease work at certain times for events such as funerals, weddings and graduations.”

Chris Harris, Black Hat Charge Hand who managed the works mentioned that even the local wildlife had a huge impact on the project:

“Due to the presence of nesting Falcons, we were working to a strict programme for the scaffold erection to ensure the birds breeding season was unaffected.”

Overall the project was a huge success, when reflecting on the project Daryl concluded:

“My favourite part was seeing the scaffold going from design to reality. It was an incredibly challenging design, but it was worth all the hours spent designing it to see it in operation and safely providing the weather protection required to complete the project.

It was a vast and complex project, but our team worked diligently and efficiently and I am delighted that we were able to hand the scaffold over ahead of schedule to allow the Ellis & Co. team to undertake the extensive restoration works. The new roof will provide better protection from coastal weather and should last for many years.

It was great to have the opportunity to play a part in preserving this incredible bit of history.

I would like to say a massive well done to everyone involved in this fantastic project.”

Source: This article was originally published in AccessPoint Magazine

Overall the project was a huge success, when reflecting on the project Daryl concluded:

“My favourite part was seeing the scaffold going from design to reality. It was an incredibly challenging design, but it was worth all the hours spent designing it to see it in operation and safely providing the weather protection required to complete the project.

It was a vast and complex project, but our team worked diligently and efficiently and I am delighted that we were able to hand the scaffold over ahead of schedule to allow the Ellis & Co. team to undertake the extensive restoration works. The new roof will provide better protection from coastal weather and should last for many years.

It was great to have the opportunity to play a part in preserving this incredible bit of history.

I would like to say a massive well done to everyone involved in this fantastic project.”